Background

The original design of RigWare provided the facility for the users to manually generate checklists. Although this was a considerable improvement on previous paper-based systems it still left scope for speeding up the process.

Challenge

A drilling customer in the USA faced challenges with their paper-based system for managing weekly equipment checklists. The manual process was time-consuming, taking up to 2 hours each week, and was prone to errors and inefficiencies. The challenge was to accelerate the generation of checklists.

Solution

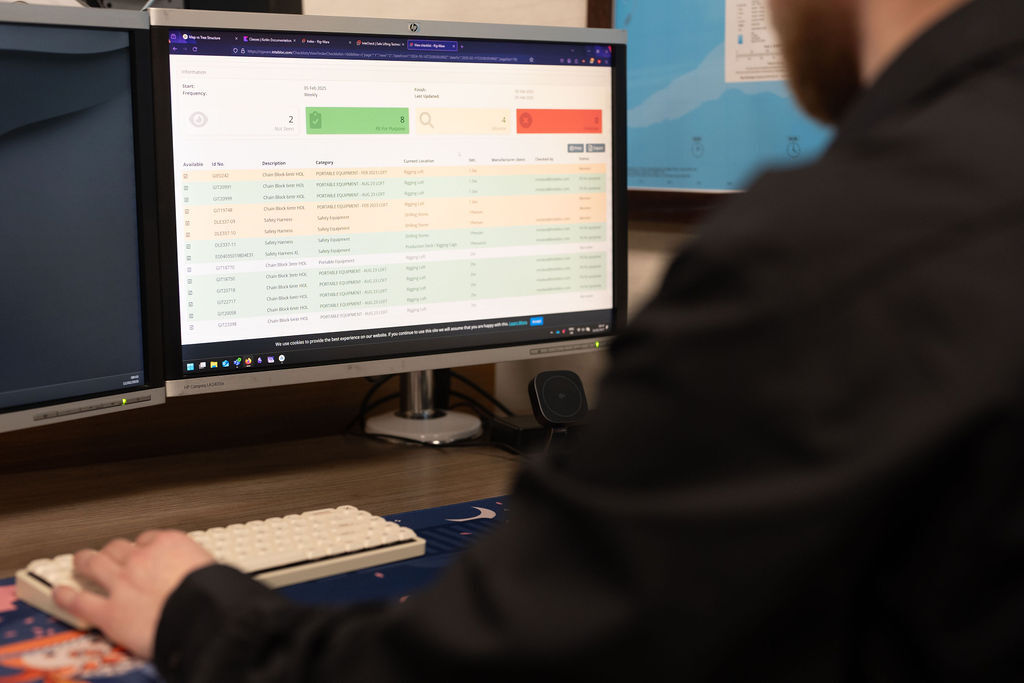

Intebloc introduced automated checklists within the RigWare™ system. These checklists are generated weekly and provide real-time locations of equipment, streamlining the entire process, significantly reducing admin times.

Implementation

- Automated Checklist Generation: The system automatically generates weekly checklists, detailing the location and status of each piece of equipment.

- User-Friendly Interface: The RigWare™ software interface was designed to be intuitive, allowing users to quickly create, access and manage their checklists.

Benefits

- Time Savings: The automated system reduced the time required for managing checklists from 2 hours to just 15 minutes per week.

- Increased Efficiency: This time savings equates to approximately 7.6 man-days per annum (91 man hours), allowing staff to focus on more critical tasks.

- Enhanced Accuracy: Automated checklists reduce the risk of human error, ensuring more accurate and reliable equipment management.

Conclusion

The implementation of automated checklists within the RigWare™ system has significantly improved the efficiency and accuracy of equipment management. This innovative solution not only saves time but also enhances overall operational effectiveness.