Background

Our client, a North Sea Operator, identified that there is a significant cost associated with procuring, renting, maintaining, and inspecting lifting equipment throughout the duration of the loft cycle. RigWare identified that equipment was being under-utilised and requested that we review the data across their assets to allow for a more focused approach when ordering lifting and safety equipment.

Challenge

Inventory Management: There was a significant amount of excess inventory, leading to higher costs and inefficient use of storage space.

Solution

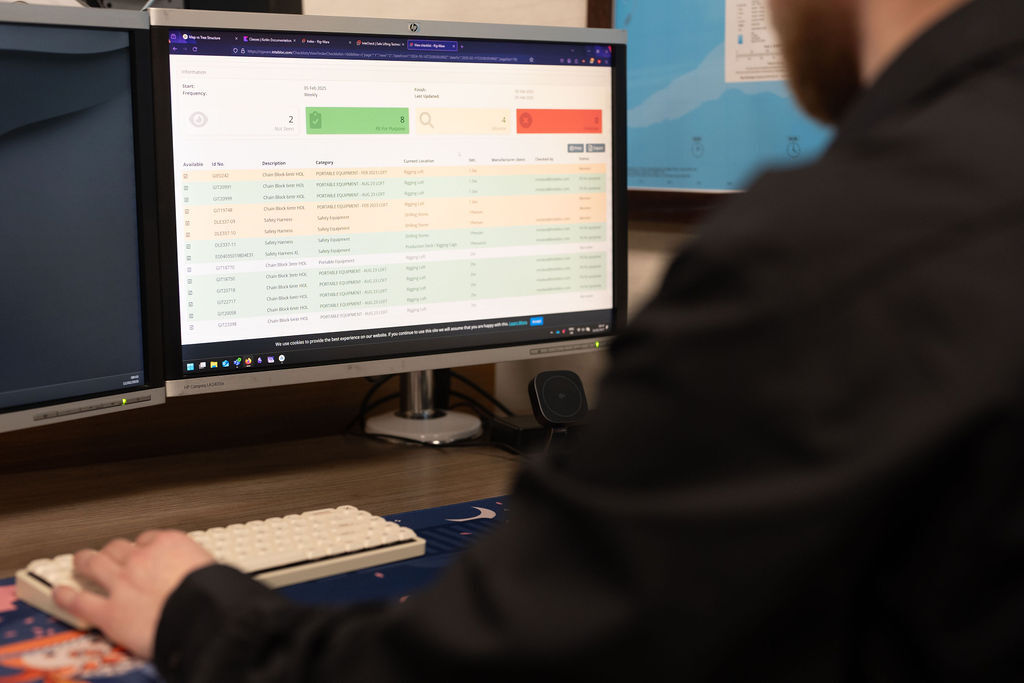

To address these challenges our client partnered with Intebloc to review the data produced both RigWare and our team. The system provided real-time data and insights into the usage and condition of the equipment, enabling more efficient and accurate equipment management.

Implementation

Intebloc worked closely with our customer to review their existing processes and identify areas for improvement. RigWare was integrated into their operations, providing a seamless transition from manual to digital management.

Benefits

The implementation of RigWare led to significant improvements in the management of lifting equipment:

- Inventory Reduction: The data demonstrated a 35-45% reduction in the inventory for the rigging lofts that are changed out on a 6-monthly basis. This reduction not only lowered costs but also minimized the storage space required.

- Operational Efficiency: With real-time data and automated processes, our customer experienced a notable increase in operational efficiency. The time spent on manual inventory checks and equipment tracking was significantly reduced.

Conclusion

RigWare, supported by Intebloc's team of specialists, significantly reduced inventory and costs while enhancing operational efficiency and safety. This case study underscores the clear advantages of digitizing lifting equipment management with RigWare, coupled with the exceptional service provided by our team.